In today’s highly competitive business landscape, industrial contractors in the food and beverage industry face numerous challenges ranging from meeting ever-increasing customer demands to ensuring product quality and safety. In such an environment, adopting lean manufacturing principles is not just a choice; it’s a necessity. Lean manufacturing can significantly improve efficiency, reduce waste, and enhance overall competitiveness for contractors in this sector.

Understanding Lean Manufacturing

Lean manufacturing is a philosophy and methodology aimed at eliminating waste, optimizing processes, and creating value for customers. It originated in the automotive industry but has since been successfully applied to various manufacturing sectors, including food and beverage production.

Key Principles of Lean Manufacturing:

1. Value-Added Focus: Identify what activities or processes add value to the final product from the customer’s perspective. Eliminate or minimize non-value-added activities.

2. Continuous Improvement: Embrace a culture of continuous improvement by constantly seeking ways to enhance processes and reduce waste.

3. Pull System: Produce items only when they are needed, reducing excess inventory and overproduction.

4. Flow: Ensure a smooth, uninterrupted flow of materials and information throughout the production process.

5. Standardization: Establish standard processes and procedures to maintain consistency and predictability.

Importance of Lean Manufacturing for Industrial Contractors in Food and Beverage Industry

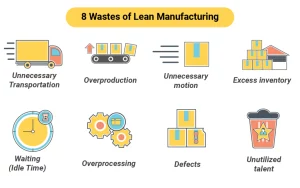

1. Waste Reduction: Lean manufacturing helps identify and eliminate various forms of waste, including overproduction, excess inventory, defects, and underutilized resources. For food and beverage contractors, reducing waste directly translates to cost savings and increased profitability.

2. Improved Efficiency: Lean principles streamline processes, minimize bottlenecks, and reduce downtime, leading to improved production efficiency. This means faster production cycles and better responsiveness to customer demands.

3. Enhanced Product Quality: Through the elimination of defects and standardized processes, lean manufacturing ensures consistent product quality. This is crucial in the food and beverage industry, where product safety and quality are paramount.

4. Flexibility and Adaptability: Lean manufacturing principles make it easier for contractors to adapt to changing customer preferences, market trends, and regulatory requirements. A flexible operation can quickly switch between product lines or make adjustments as needed.

5. Cost Reduction: By optimizing processes and reducing waste, lean manufacturing leads to lower production costs. Contractors can allocate resources more efficiently, ultimately reducing the cost of goods sold.

6. Increased Customer Satisfaction: Lean manufacturing’s focus on value-added activities and quality improvements directly benefits the end consumer. Satisfied customers are more likely to remain loyal and provide repeat business.

7. Regulatory Compliance: The food and beverage industry is subject to stringent regulatory standards. Lean manufacturing practices help ensure compliance with food safety regulations and facilitate documentation and traceability.

Case Studies in Lean Manufacturing Success

Several renowned food and beverage companies have successfully implemented lean manufacturing principles to their advantage. For instance, Toyota’s production system, often considered the archetype of lean manufacturing, has been adapted by companies like Starbucks, Nestlé, and Coca-Cola to streamline their operations and meet customer demand efficiently.

Industrial contractors specializing in the food and beverage industry must adopt lean manufacturing principles to thrive. By reducing waste, improving efficiency, enhancing product quality, and staying adaptable, lean manufacturing empowers contractors to not only meet customer demands but also maintain a competitive edge in a rapidly evolving market. Embracing lean manufacturing is not just a choice; it’s an imperative for success in this industry.

Gottstein Corporation is at the forefront of integrating lean manufacturing methodologies into its operations. To delve into their offerings and experience their application of these principles firsthand, please navigate to their services page via the following link.

Should you have any questions regarding this post or mentioned services, please submit your query below.