In the fast-moving and ever-evolving industrial landscape, precision, quality, and efficiency are fundamental to operational success and competitiveness. Gottstein Corporation has been an industry leader for over 35 years, delivering full-scale fabrication and machining services that empower manufacturers, plant operators, contractors, and engineers across multiple sectors.

Our dedication to combining state-of-the-art cutting-edge technologies with decades of expertise from our skilled engineers and technicians makes Gottstein Corporation the reliable partner your facility needs to meet strict lead times, reduce costly downtime, and optimize your production workflows.

Our Full-Service Fabrication and Machining Capabilities

At the heart of Gottstein’s operations is a fully equipped fabrication and machining shop featuring precision lathes, presses, milling machines, multi-axis CNC equipment, and advanced welding supported by AWS-certified welders.

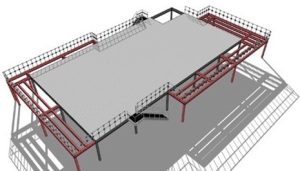

Operating seven days a week, our machine shop supports a broad range of industrial needs—from specialized prototypes to high-volume production runs. Our skilled technicians excel in custom machining and part fabrication supported by rapid prototyping using innovative 2D/3D CAD modeling. We also fabricate platforms, catwalks, handrails, and critical structural components designed for your industrial facility’s unique requirements.

Additionally, we offer extensive troubleshooting and repair services to minimize unexpected downtime with emergency part fabrication and 24/7 responsive support, which you can explore further on our contracting services page.

Cutting-Edge Technologies Driving Precision

OMAX Maxiem 1530 Abrasive Waterjet Cutting

The Maxiem 1530 waterjet cutter offers superior versatility and precision by cutting complex geometries using a focused abrasive waterjet stream. It supports a wide range of materials, including metals, ceramics, glass, composites, and rubber. Because it is heat-free, this method avoids thermal distortion and preserves critical material properties. The Maxiem 1530 enables us to execute designs with intricate details such as sharp corners, bevels, and minimal inner radii—vital for industrial components requiring tight tolerances and structural integrity.

Bend-Tech Dragon A400 Plasma and CNC Tube Cutting

Our Bend-Tech Dragon A400 plasma cutter specializes in rapid, accurate cutting of thick and large-diameter pipes and sheets commonly used in structural and piping applications. Its CNC tube cutting capabilities allow fabrication of complex customized parts that integrate seamlessly into larger assemblies. Additional engraving and marking functionalities enable enhanced component customization.

Engineering, Prototyping, and Quality Control

Precision cutting and machining are integrated with our engineering and prototyping teams, who utilize modern CAD software to develop and validate 2D and 3D models prior to fabrication. This minimizes costly revisions and ensures parts meet both industrial regulations and client expectations.

To learn more about our engineering expertise, visit our contracting and engineering services page.

Our prototyping capabilities include CNC milling, turning, laser engraving, and multi-axis machining optimized for parts with tight tolerances. Every project undergoes rigorous quality control and comprehensive testing for durability and reliability.

Comprehensive Industrial Services Beyond Machining

Besides precision fabrication, Gottstein Corporation provides a full suite of industrial services, including equipment installation, conveyor system design, turnkey contracting with permitting and multi-trade coordination, plant relocations, shutdowns, and 24/7 emergency repairs. We also offer in-house inventory and supply chain management for industrial maintenance.

Our end-to-end approach is designed to streamline projects and reduce operational complexities for clients. Learn more about our broad range of services on the Gottstein Corporation website.

Why Choose Gottstein Corporation?

-

-Over 35 years of expertise in machining and fabrication

-

-Advanced and reliable technologies like OMAX Maxiem 1530 and Bend-Tech Dragon A400

-

-AWS-certified welders and experienced technical staff committed to quality and safety

-

-Flexible solutions ranging from prototypes to full production runs

-

-24/7 emergency support to minimize operational downtime

Discover how Gottstein continues solving industrial challenges worldwide.

Partnering with Gottstein Corporation guarantees a combination of innovative technology, skilled craftsmanship, and full-service support to deliver precision fabrications critical for your facility’s performance and efficiency.